Scheduling paradox: Going slower to finish faster

Sometimes you have to slow down in order to reach your destination faster. Sounds contradicting, doesn’t it? Well it’s true nonetheless.

In a previous article, we introduced takt time planning on a theoretical level. However, some principles are best understood when supported with an example.

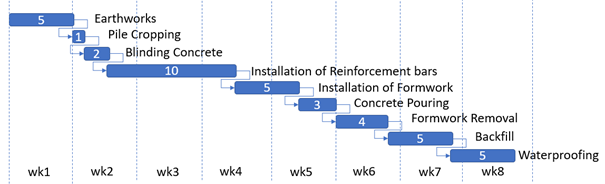

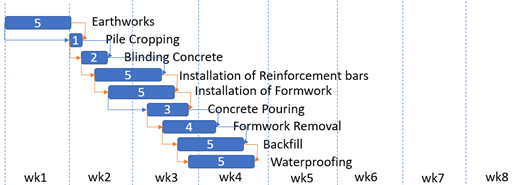

The other day I was planning a project in a traditional CPM way when the PM came to me and said: “we have to speed up a lot”. Everything that’s linked finished to start doesn’t really have to wait until the previous activity is entirely finished. They should overlap as much as possible but always leave a day lead to start or finish the next trade. Also double the resources for Reinforcement installation.” Soon enough my planning went from the above to the one below, using a lot of SS- and FF- links with lags. Notice that the relationships in orange depict driving relationships.

The operation reduced the schedule from 39 workdays to 19. Not too bad I would say. However, the PM wasn’t fully satisfied. “Which activities’ duration should we change to reduce the schedule to 3 weeks?”

Earthworks is an obvious candidate. It’s the only activity where decreasing its duration would decrease the overall length of the schedule. However due to mobility on site it wasn’t possible to reduce earthworks to less than 3 days bare minimum. Also, the rebar installation was limited to at least 5 working days due to resource constraints.

Can you figure out a solution that would fit inside 3 weeks?

Try as you like, with the above limits and using the standard tool of speeding up critical activities, you’ll only get to 16 days tops.

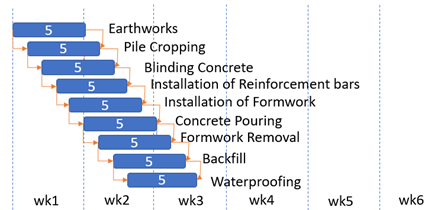

However, the solution can be found using takt time planning. Instead of looking for tiny improvements, go for one continuous flow. By defining your takt, and allowing all your trades to have the same duration, an optimal solution can be found.

Contradictory to our intuition, extending the duration of activities such as ‘Pile Cropping’ and ‘Blinding Concrete’ have had a positive effect on the duration of the overall schedule. We even managed to gather 2 days of positive float!

Did you notice the solution right away? Have you got questions regarding takt and what it can mean for your projects? Let us know in the comments.

This blog is originally placed on Primaned.be op 27 March.